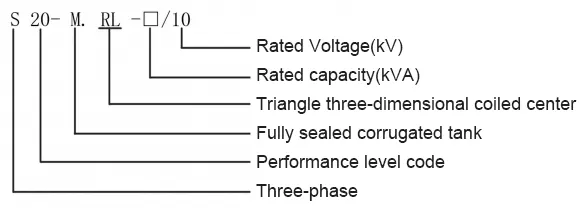

S20 type delta three-dimensional coil-core sealed power transformer

This product is outdoor use oil-immersed power transformer, coil structure for non-circular concentric coil, short circuit impedance of 4.0, 4.5, 5.0, temperature rise limit value of 60K, belongs to the second level of oil-immersed transformer energy consumption models.

Description

This product is outdoor use oil-immersed power transformer, coil structure for non-circular concentric coil, short circuit impedance of 4.0, 4.5, 5.0, temperature rise limit value of 60K, belongs to the second level of oil-immersed transformer energy consumption models. s indicates three-phase, 20 indicates the energy consumption level sequence code, S20 transformer refers to the performance level of 20 oil-immersed transformer, in line with the “GB 20052-2020” power transformer energy efficiency limit value and energy efficiency level in the national power transformer secondary energy efficiency standard requirements, usually referred to as secondary energy efficiency transformer. Power transformer energy efficiency limit value and energy efficiency level” in the national power transformer secondary energy efficiency standard requirements, usually also known as secondary energy efficiency transformer.

S20 transformer is our company in S13 transformer based on new materials, new technology and independent innovation combined, through the transformer core and coil structure optimization design, to reduce transformer no-load loss, load loss and noise purpose. s20 transformer rated voltage 10kV, capacity including 80kVA, 160kVA, 250kVA, 400kVA. 630kVA, 800kVA, 400kVA, 630kVA, 800kVA, 1000kVA, 1250kVA, 1600kVA, 2000kVA, 2500KVA, etc. The difference between S20 transformer and S13 transformer is mainly reflected in the loss, S20 transformer than S13 transformer no-load loss and load loss are reduced by 10%, that is to say, the S20-M series of transformers are more in line with the national concept of energy saving and emission reduction. In other words, S20-M series transformer is more in line with the national concept of energy saving and emission reduction, and is also the future focus on pushing the oil-immersed transformer model.

Model Meaning

Technical Advantages

Energy Savings ● Three-phase balancing ● Low no-load losses ● Low no-load current ● Material saving | Green ● Low operating noise ● Small electromagnetic distortion rate | Safe and reliable ● Strong short-circuit resistance ● Low temperature rise at hot spots ● Good heat dissipation |

Product Features

Material savings

● 4 yokes reduced to 3 yokes, 25% savings in yoke section.

● Corner mass is reduced by half, saving material by about 5%.

● No V-shaped and sharp corner section waste.

● Filling factor 0.89-0.93 increased to 0.97-0.99.

● Average length of coil reduced by 2-3%, saving copper 2.

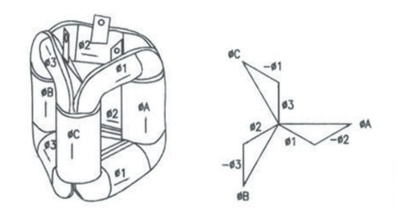

Three-phase magnetic circuit balance

● The lengths are exactly equal and the sum of the lengths is the shortest.

● The three-phase no-load currents are perfectly balanced.

Improved no-load performance

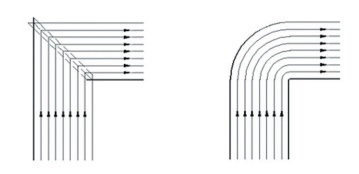

● There are no seams between the layers of three-dimensional coiled iron core, no air gap.

● Uniform distribution of magnetic circuit, no high resistance area, no flux density distortion phenomenon at the joints.

● The direction of magnetic flux is exactly the same as the rolling direction of silicon steel sheet.

High resistance to short circuits

● The clamp is a one-piece frame structure with high strength and even pressure.

● The compression pads are distributed around the coil, and the three-phase coil is subjected to uniform force.

● Coil compression area is increased by about 15%.

● Round coil with uniform force in the amplitude direction.

Production Process

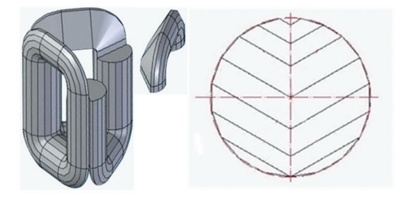

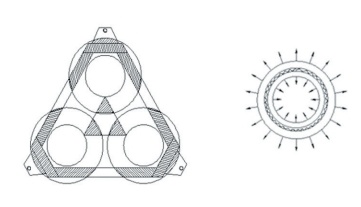

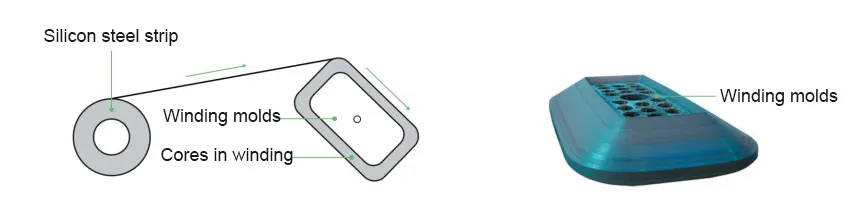

Cubic Coil Cores

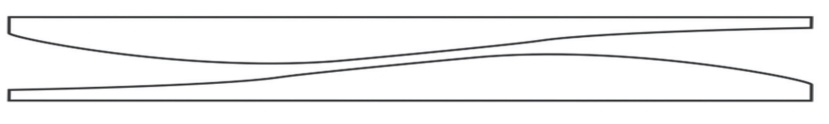

Three-dimensional rolled iron core adopts high-performance oriented silicon steel sheet, through the curve shear and asymmetric winding, the cross-section of the core frame is semi-circular with a 30-degree inclination angle, and three identical core frames are assembled to become a three-dimensional rolled iron core whose cross-section of the core column is approximately circular and the top view direction is a three-dimensional arrangement of the positive triangle.

Cutting and winding

Annealing and assembly

Conditions of use

The maximum ambient temperature is not more than +40℃, the minimum temperature is not less than -25℃, the maximum monthly average temperature is +30℃, the maximum annual average temperature is +20℃.

The altitude does not exceed 1000m.

No gas vapors, chemical deposits, dust and dirt and other explosive and erosive media that seriously affect the transformer.

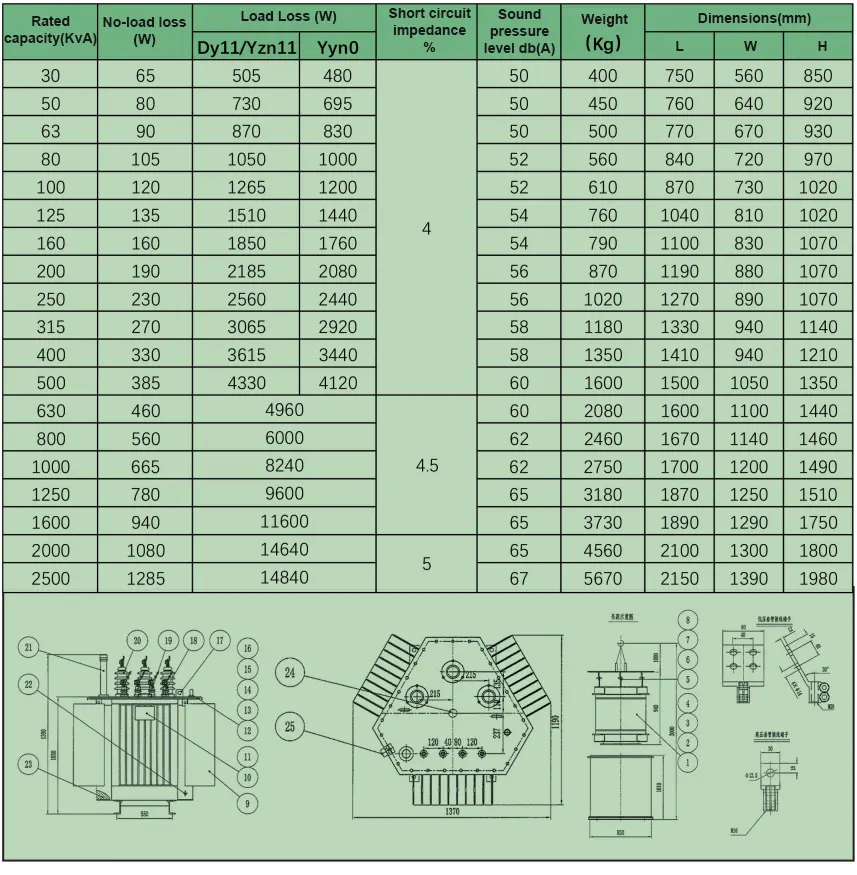

Technical parameters and installation dimensions

Transformers