Epoxy resin casting dry type power transformer

This series of epoxy resin casting dry-type transformer materials of high quality, the formula is scientific, using advanced production and testing equipment according to the strict process of production and become. The product is characterized by high reliability and long service life.

Description

This series of epoxy resin casting dry-type transformer materials of high quality, the formula is scientific, using advanced production and testing equipment according to the strict process of production and become. The product is characterized by high reliability and long service life. According to different use environment, can be configured with different protection level shell or not configured shell. Applicable to high-rise buildings, commercial centers, airports, tunnels, chemical plants, nuclear power plants, ships and other important or special environmental sites.

Adopting proprietary dry-type transformer local discharge control process and casting internal stress control technology, the internal insulation of cast dry-type transformer is controlled in the most ideal state, thus ensuring the key performance of dry-type transformer

During the design process, the field strength of the product is analyzed and calculated, and by adjusting the relevant parameters, the field strength of each component is below 75% of the starting field strength of the insulating material, which ensures the advanced technical performance of the product.

When designing the product, the relevant performance parameters are introduced into the design process in advance, so that the design input of the product already contains the relevant requirements, and the output is more in line with the needs.

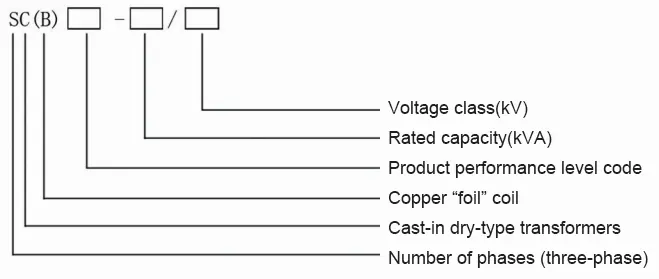

Model Meaning

Product Features

● Safe, fireproof, no pollution, can run directly in the load center.

● Adopting German HTT technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability and long service life.

● Low loss, low noise, obvious energy-saving effect, maintenance-free.

● Good heat dissipation performance, strong overload ability, and can increase capacity operation when forced air cooling.

● Good moisture-proof performance, adapt to high humidity and other harsh environments.

● It can be equipped with perfect temperature monitoring and protection system. Adopting intelligent signal temperature control system, it can automatically monitor and itinerantly display the working temperature of each of the three-phase windings, and can automatically start and stop the fan with alarm, trip and other function settings.

● Small volume, light weight, occupying less space, low installation cost.

Structural features

● The core is made of high quality cold rolled silicon steel sheet, 45 degree step full oblique seam structure, using three shears and two punches to de-angle the core cross-cutting process and five steps step shear and stacked iron process, improving the flux distribution at the seam, reducing the vibration energy of the core. The core is cured in one piece and the surface is sealed with insulating resin, which effectively reduces no-load loss, no-load current and core noise. +High-voltage coils are wound with high-quality F-grade insulated copper wires and internationally advanced insulating materials, and larger capacity coils are equipped with heat dissipation air channels along the axial direction. This structure has good resistance to current impact, temperature change, cracking and excellent heat dissipation performance. Adopting multi-stage segmented cylindrical structure, it has strong ability to withstand over-voltage and very low partial discharge level. The coils are molded and cast after vacuum drying. The whole casting and curing process is completed according to the pre-programmed process curve, and the precise process control ensures that the coils are free of air holes and cavities.

● Low-voltage coil adopts foil structure, which effectively solves the problem of ampere-turn imbalance of low-voltage and high-current coils with wire winding type. Meanwhile, there is no axial turns and axial winding helix angle in foil coils, which effectively eliminates the axial force of the transformer in case of short-circuiting, and ensures that the current density inside the coil can be adjusted axially according to the distribution of the load of the high-voltage coils, which reduces the radial force of the low-voltage short-circuit in case of a sudden short-circuiting. After winding, the coil ends are sealed and cured with resin, avoiding the entry of all kinds of foreign matter and moisture.

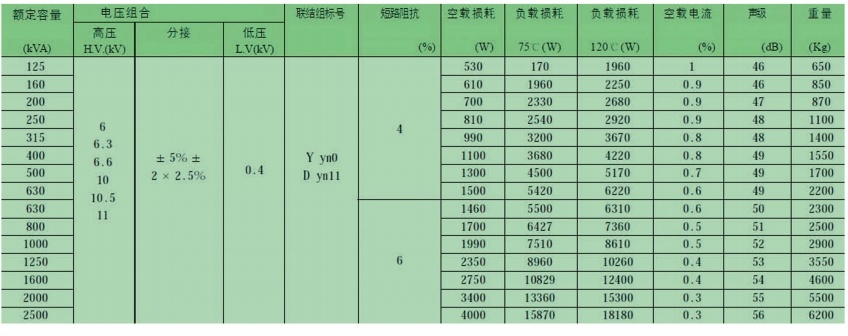

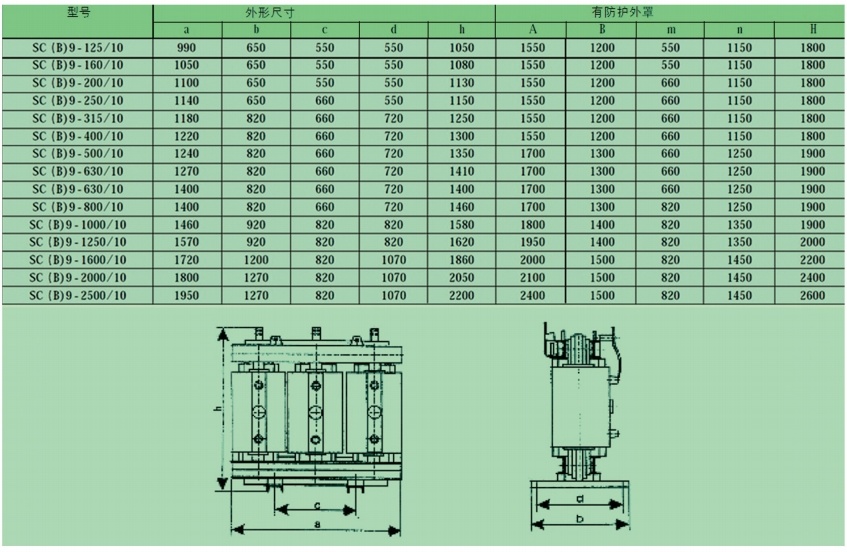

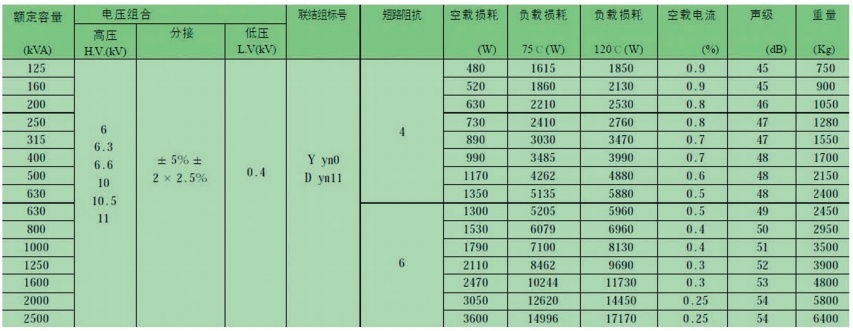

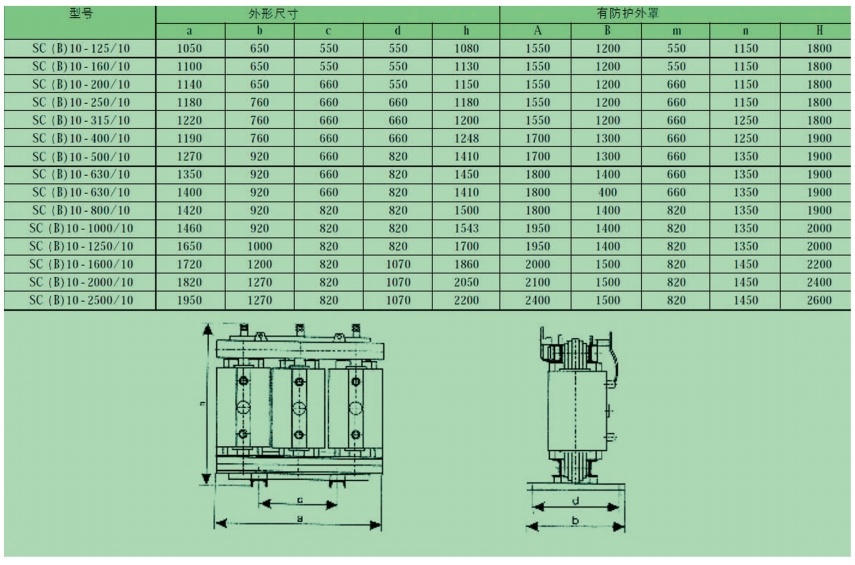

Technical parameters and installation dimensions

SC(B)9-125~2500-10 series dry-type transformer

SC(B)10-125~2500-10 series dry-type transformer

Transformers