SC(B)-RL epoxy resin casting three-dimensional rolled iron core dry-type transformer

This product is characterized by high safety, strong overload capacity, environmental protection, no-load loss, small excitation current, low noise, moisture-proof, corrosion-proof, strong short-circuit resistance, good performance in withstanding impact overvoltage, small volume, light weight and beautiful appearance.

Description

This product is characterized by high safety, strong overload capacity, environmental protection, no-load loss, small excitation current, low noise, moisture-proof, corrosion-proof, strong short-circuit resistance, good performance in withstanding impact overvoltage, small volume, light weight and beautiful appearance. The main performance index of the product is better than the domestic standard.

It is most suitable for use in environments with high fire protection requirements, and is applicable to high-rise residential buildings, airports, stations and terminals, railroads, hospitals, power plants, metallurgical industry, shopping centers, residential densely populated areas, and petrochemical, nuclear power plants, nuclear submarines and other places.

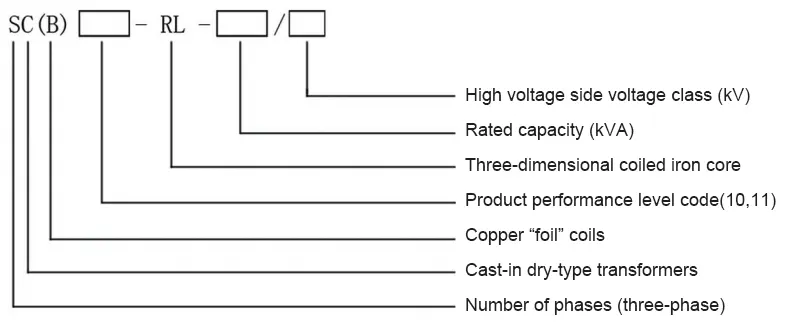

Model Meaning

Product Characteristics

Angular coil core in the high and low voltage coils in each turn of the coil is wrapped with heat-resistant 180 ℃ and above, fire retardant, electrical mechanical strength of the insulation layer, three-dimensional triangular coil core and high and low voltage coils as a whole attached to a layer of heat-resistant 180 ℃ and above through the vacuum pressure impregnated, moisture, high electrical mechanical strength of insulating varnish. With temperature control system, distribution transformer intelligent terminal TT and on-load voltage regulator tap-changer equipment, applicable to a wide range can be widely used in high-rise buildings, residential neighborhoods and fire prevention requirements of the place. It is maintenance-free and saves operating costs.

Structural Characteristics

Three-dimensional triangle core

Adopting three-dimensional triangular structure, the arrangement of the core is more reasonable combination, using three identical single-frame assembled into a three-dimensional equilateral triangle, to realize the product's three-phase core magnetic circuit is completely symmetrical and equal to ensure that the three-phase power supply is balanced, and make the magnetoresistance is greatly reduced, and the excitation current and the no-load loss are significantly reduced. It has the following advantages.

Significant energy-saving effect: three-dimensional triangular cores have no seams, i.e. there is no high energy consumption area, which can give full play to the high permeability characteristics of high-quality core materials and minimize the loss caused by the air gap formed at the seams.

Miniaturization: high space utilization coefficient, the transformer adopts triangular structure, so the volume is smaller than the conventional transformer, compact structure, beautiful appearance, small footprint.

Low noise: because the three-dimensional triangle coil core is made of several kinds of trapezoidal material belt sequentially coiled into, silicon steel belt coiled tightly between the silicon steel belt, silicon steel belt conductivity direction and the core of the magnetic circuit direction is completely consistent with the work of the vibration is small, can be solved due to the stacked core of the magnetic circuit is not coherent and the noise issued by the noise, the noise can be reduced to the lowest limit.

Winding

The coil consists of high-voltage coil and low-voltage coil, the low-voltage coil is of cylindrical structure, and the end insulation is sealed with resin mixture; the high-voltage coil adopts segmented cylindrical structure, and the whole coil conductor is sealed by epoxy resin solid insulation layer. Meanwhile, 315kVA and above capacity low voltage adopts foil winding. Low-voltage foil winding has the following advantages: there is no helix angle at both ends of the coil, so the unbalanced ampere-turns are greatly reduced. The short-circuit resistance can be greatly enhanced. The number of turns of the winding is arranged according to the amplitude direction, and the air duct can be set more flexibly, which has strong heat dissipation performance.

Low-voltage foil winding has the following advantages: there is no helix angle at both ends of the coil, so the unbalanced ampere-turns are greatly reduced. The short-circuit resistance can be greatly enhanced. The number of turns of the winding is arranged according to the amplitude direction, and the air duct can be set more flexibly, which has strong heat dissipation performance.

Large capacitance between winding turns, small potential gradient, strong resistance to shock voltage.

Vacuum pressure casting

High-voltage using thin insulation casting structure, in the vacuum state (46mbar) with epoxy resin mixed filler casting. The casting process is strictly controlled baking, preheating, vacuum casting, keeping vacuum, unloading pressure, gelation, demolding, curing and other processes to control the temperature and vacuum, to prevent the winding from bubbles, cracking and other defects after casting.

The cast resin mixture can be completely immersed into the coil of each gap to eliminate the existence of voids, effectively inhibit the partial discharge phenomenon, the amount of partial discharge does not exceed 5PC.

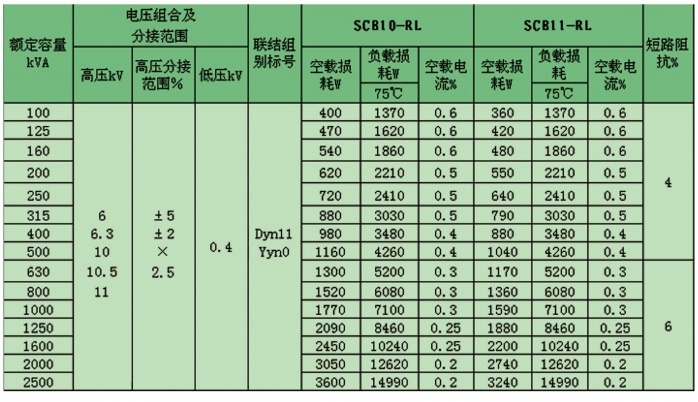

Technical Parameters

SCB series epoxy resin casting F class thousand type transformer performance indicators

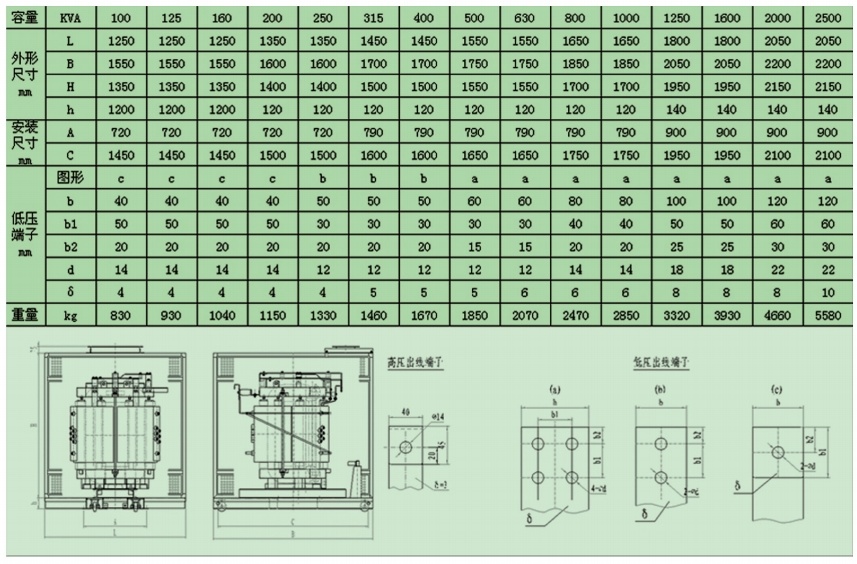

Mounting Dimensions

Transformers